Our goal to consistently meet or exceed your expectation.

We are firmly committed to supplying high-quality custom manufactured components and assemblies. From our certified engineers and trained machinists to our maintained and calibrated equipment, our assembly floor keeps in line with quality and inspection standards.

Our Inspection Assurances

No matter the industry, providing the highest-quality precision component parts to our customers is priority one. Our team is dedicated to quality inspection for part accuracy and consistency to meet customer satisfaction.

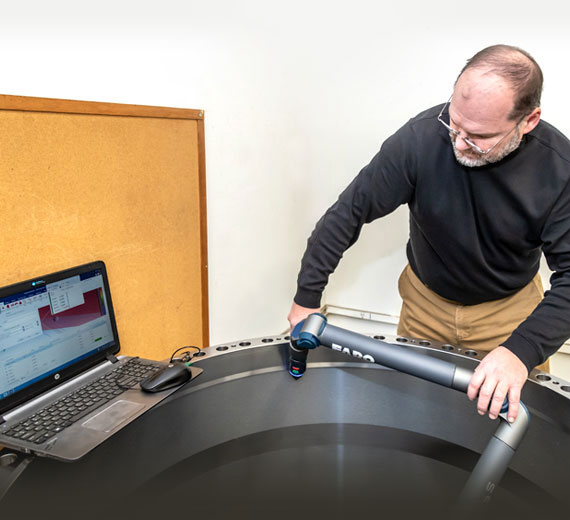

Whether manual or CMM, inspections may be performed as part of a FAI (First Article Inspection), PPAP (Production Part Approval Process), NCI (New Component Introduction) or special requirements to customer specifications. We help address ongoing needs, while maintaining your project integrity, with quality assurance you can trust.

Effective Customer Communication

York-Seaway’s team of experts document every detail of our rigorous parts inspection process from the outset, so customers get the utmost transparency into the quality of their component parts.

Measured Results

Our quality inspections include measuring and evaluating all dimensional characteristics and their corresponding geometrical tolerancing critical to performance.

Customer Expectation

Your projects need to be pristine — and so do your component parts. When it comes to quality, timeframe and compliance, York-Seaway aims to exceed customer expectations, so you trust you’re receiving the best value for your project investment.

Additional Inspection Services

In-process inspections are FAI and operator inspections that ensure our quality and on-time delivery of completed orders to our customers.

Inspection and Quality Control Equipment/Capabilities

| Inspection Characteristics & Properties | Dimensional Concentricity Contour Roundness Straightness |

| Inspection Methods | Coordinate Measuring Machines (CMM): a mechanical system designed to move a measuring probe to determine coordinates of points on the surface of a work piece. |

| Equipment | CMM Brown & Sharp Shop Floor/CMM FARO Quantum Visual Comparator |

| Value-Added Services | Assembly CAD CAM Fabrication Machining Product Design Assistance Product Development Testing |

| Typical Lead Time | Quoted on a job-by-job basis |

Tell us about your project!

We love to hear about what you’re tackling. Get in touch with us and we’ll show you how York-Seaway experts can get the job done right.